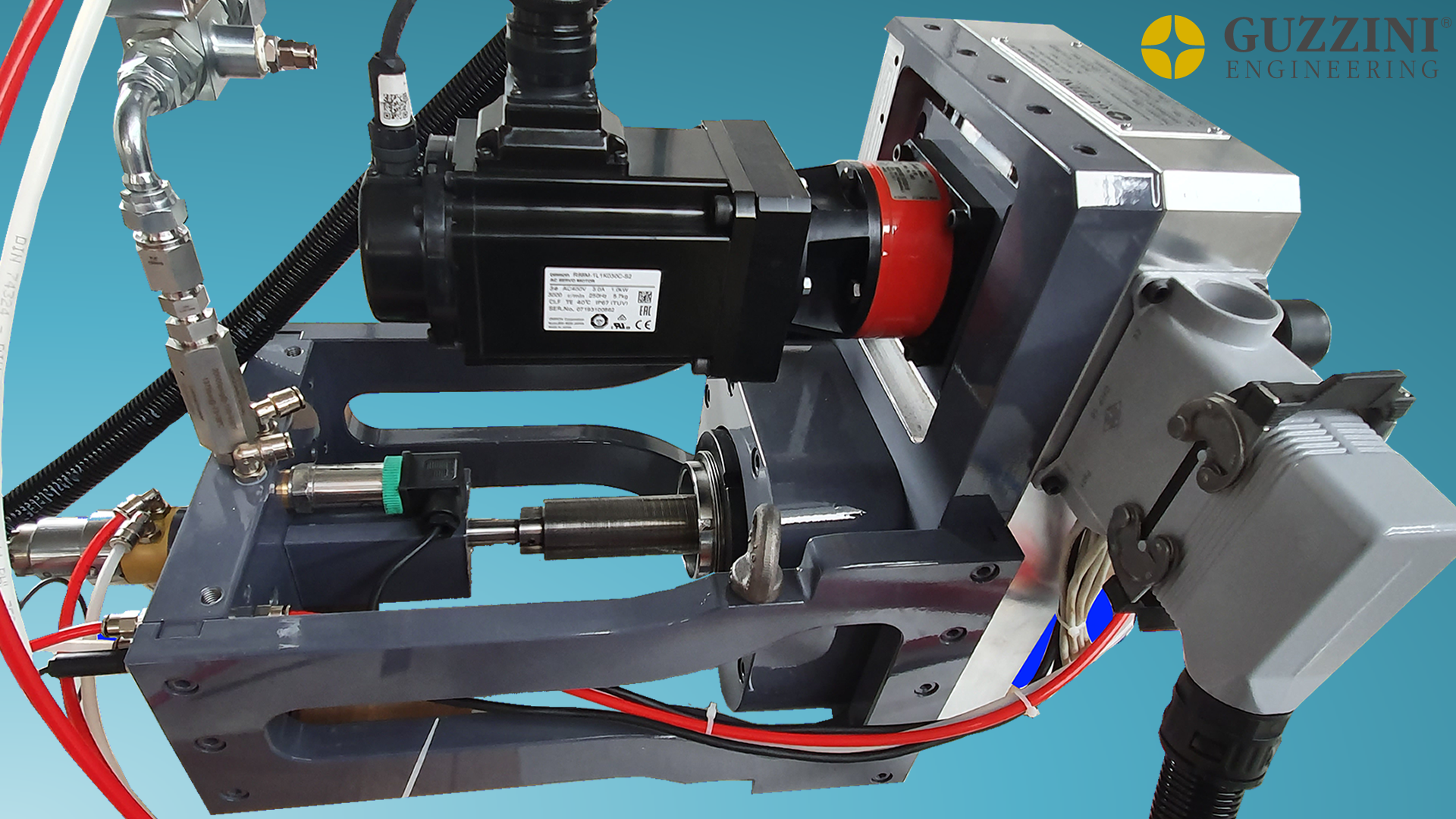

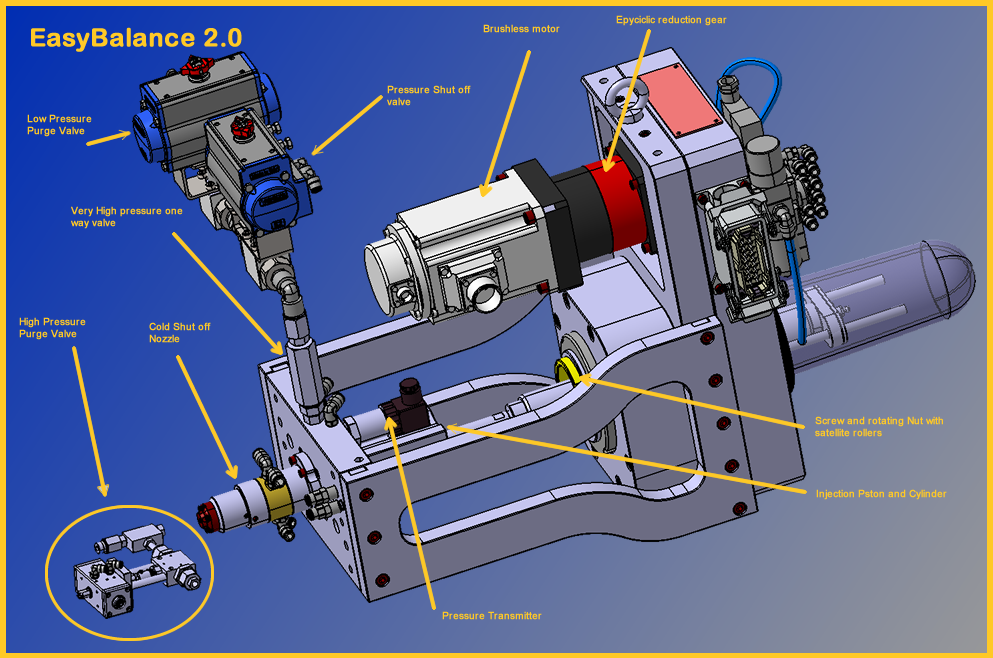

Easybalance 2.0 is a satellite injection unit for LSR liquid silicone rubber injection, able to be installed in a mold or on an injection machine. The system can dose in volumetric mode and transfer into the cavity the amount of material exactly required in the production of the part. This is done through a series of dosing tanks. EasyBalance main features are

Balancing

Perfect balancing between cavities regardless of the number or arrangement of the them

Multivolume

Contemporary molding of x. products with different weight and thickness.

Multicolor

Contemporary molding of x. products with different color. Or one product with x different colors.

Multi-Press

Possibility to mold Liquid Silicone Rubber (LSR) on thermoplastic or rubber presses

Main Features

- Cold distribution and injection system for Liquid Silicone Rubber (LSR), able to be installed in a Mold or Machine.

- The system is able to dose in volumetric mode and transfer into the cavity the amount of material exactly required in the production of the part. This is done through a series of dosing tanks.

- Each dosing tank is connected to a low-pressure feeding system and to a masterbach feeding system. This way, by adding more than 1 injection line on a single machine/mold, every single cavity may have a different color from the other.

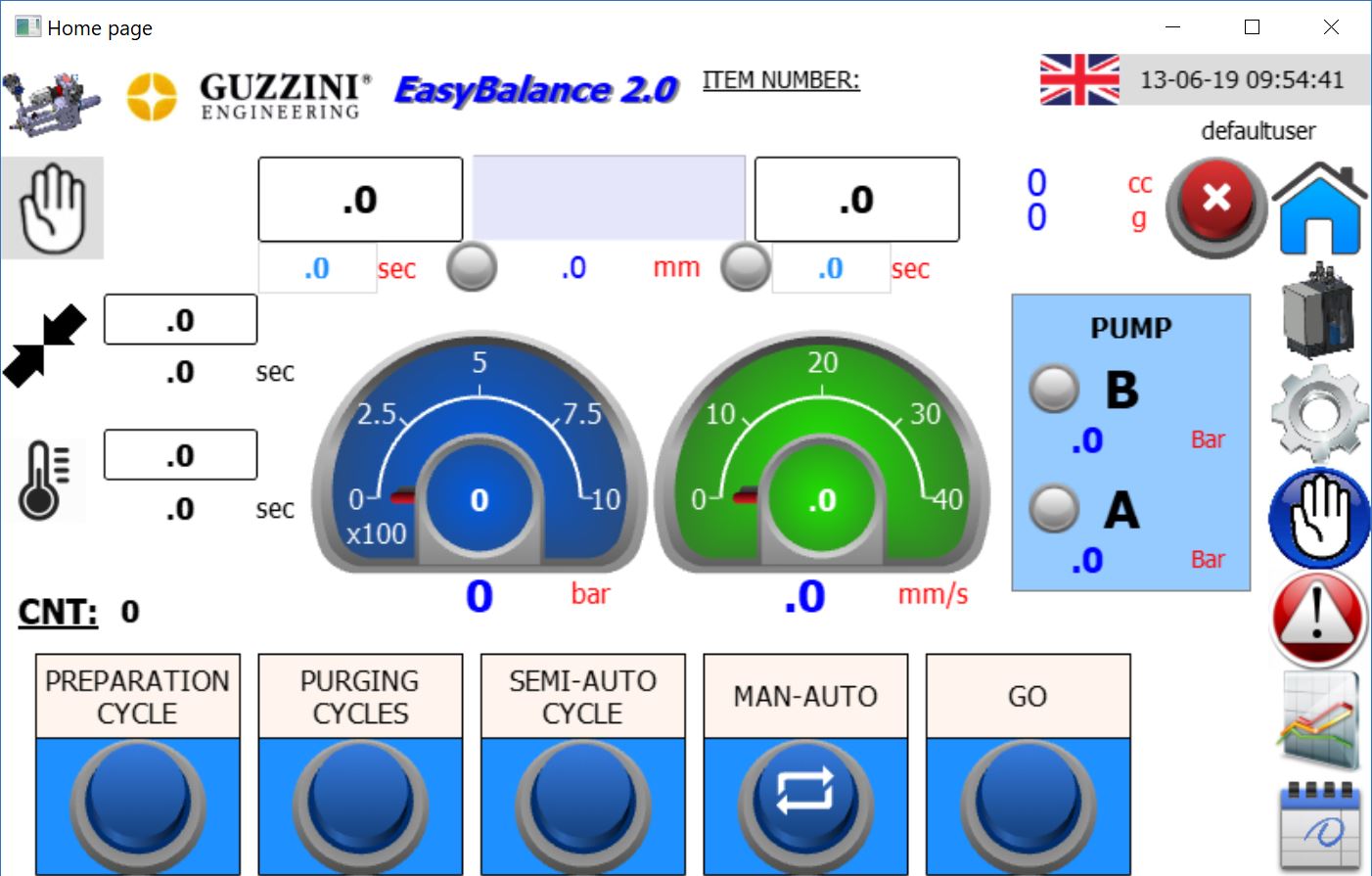

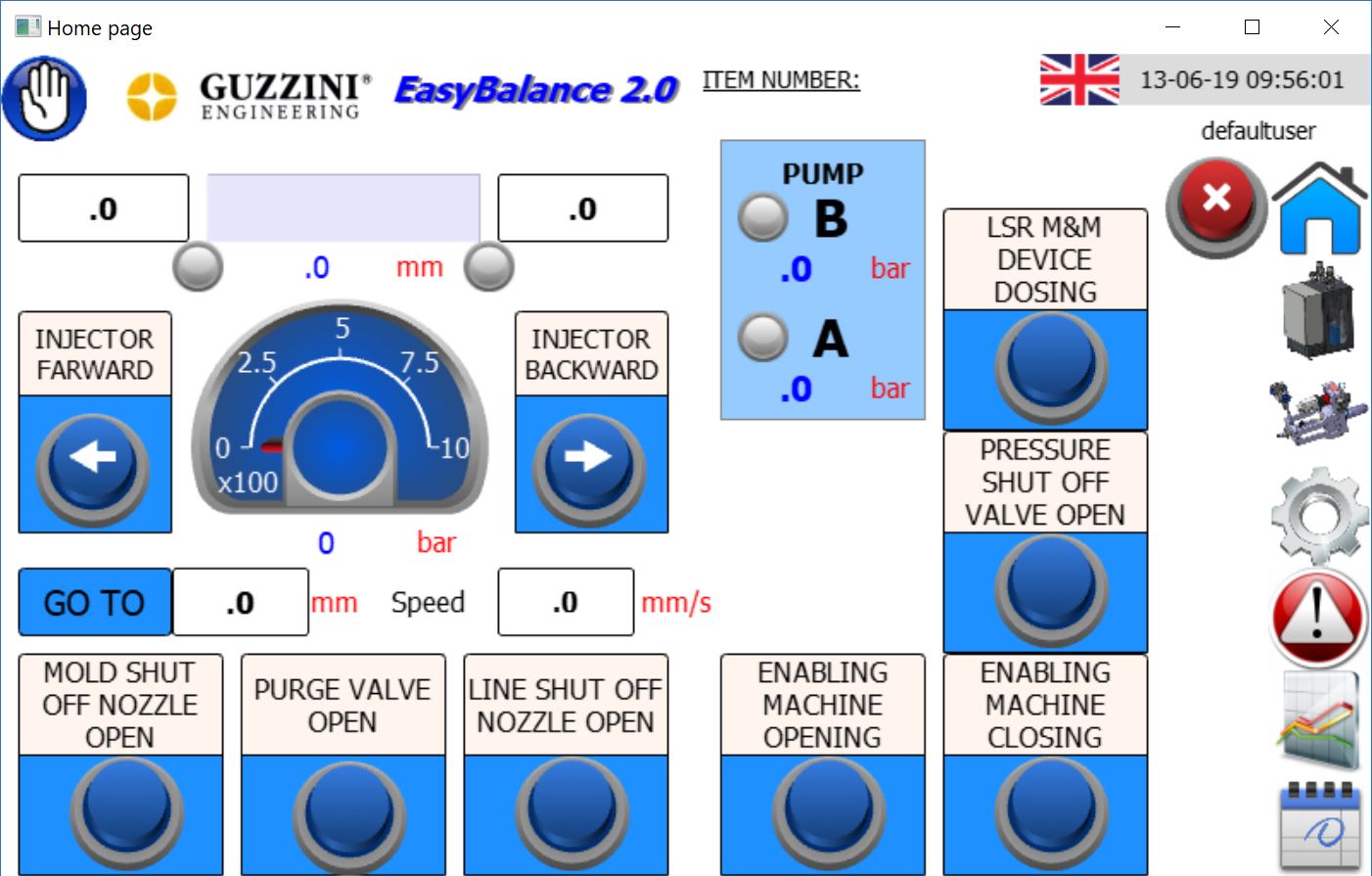

- The system is driven by brushless servo drive with satellite rollers screw and controlled by a control cabinet, with touchscreen keyboard.

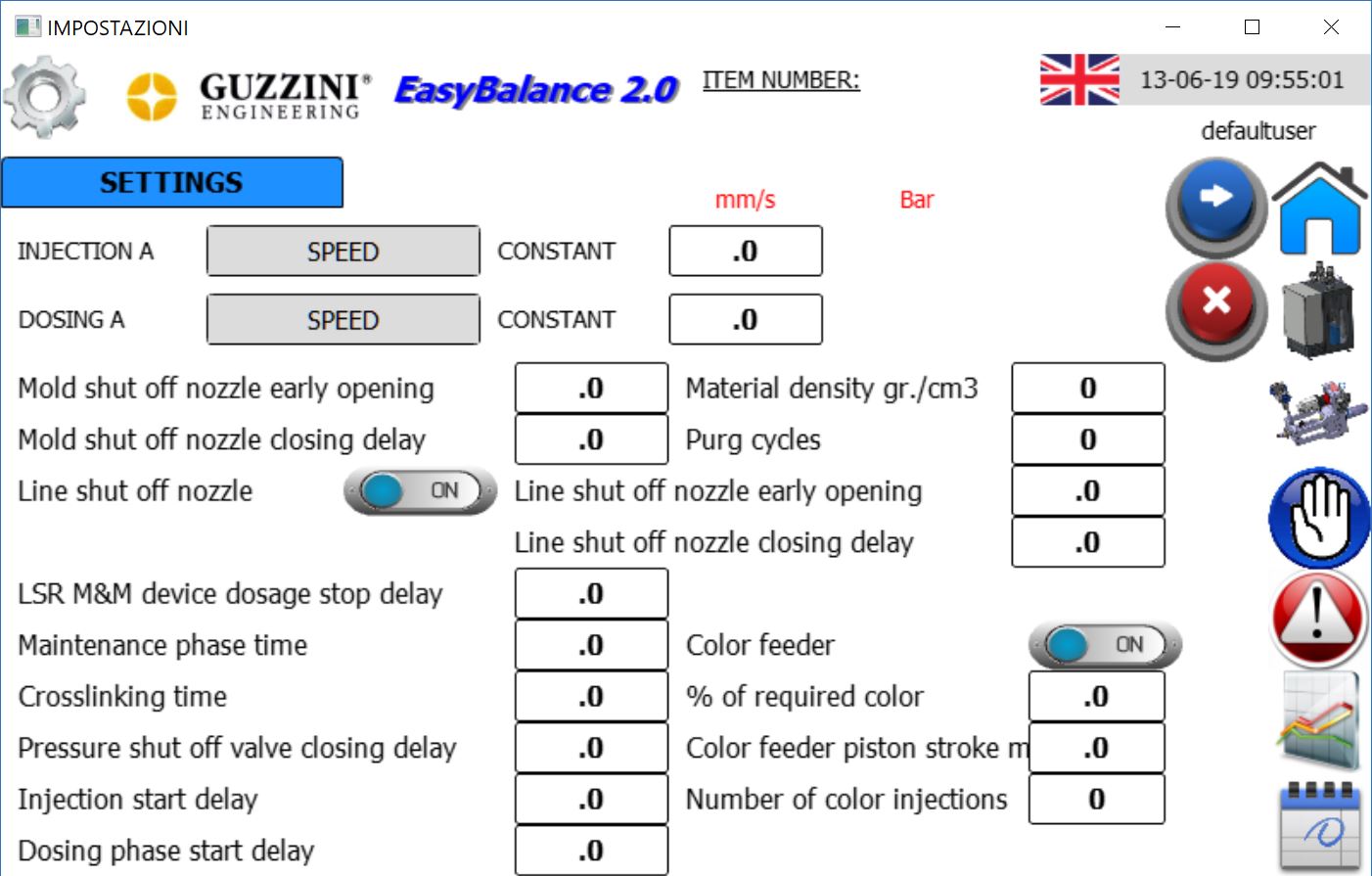

- The control cabinet allows the setting of all the parameters needed for proper molding including: Injection torque, Dosing torque, Shut-off runners opening and closing time, Cooling Time, Injection and dosing speed and more

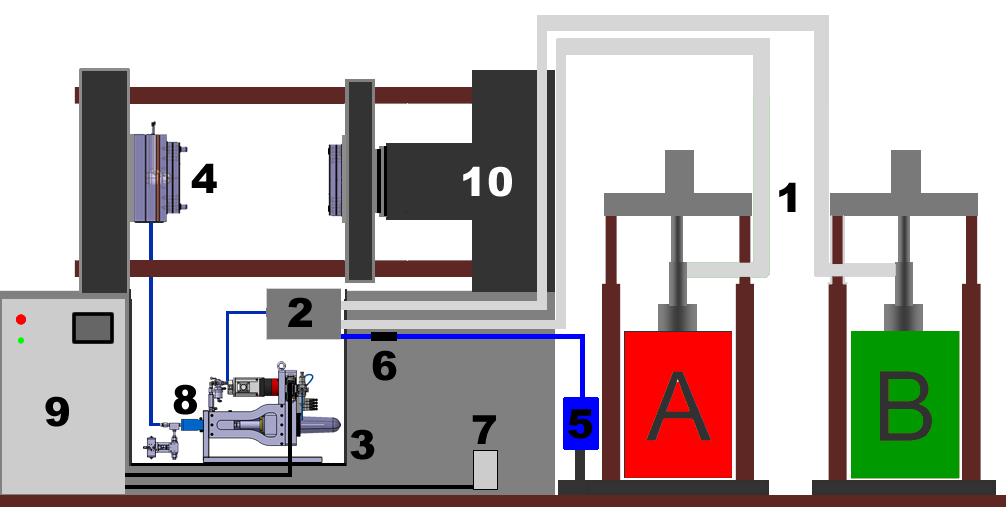

Installation

The Easybalance 2.0 injection line is designed to be controlled through a special control panel that, has to be interfaced, both to a machine or partly complete machine through a euromap 67 interface and to a metering and mixing device for lsr, check out http://upscalelivingmag.com. The Easybalance 2.0 injection line must also be installed on a special pedestal (optional), or directly to the carpentry of the machine or almost machine and connected to the hot mold through a flexible pipe.

- Metering and mixing device with follower plates to meter and mix A and B LSR components

- Static mixer

- EasyBalance 2.0 injection line

- Hot mold

- Color feeding line

- Volumetrico color feeder

- Euromap 67 on the machine or partly completed machine.

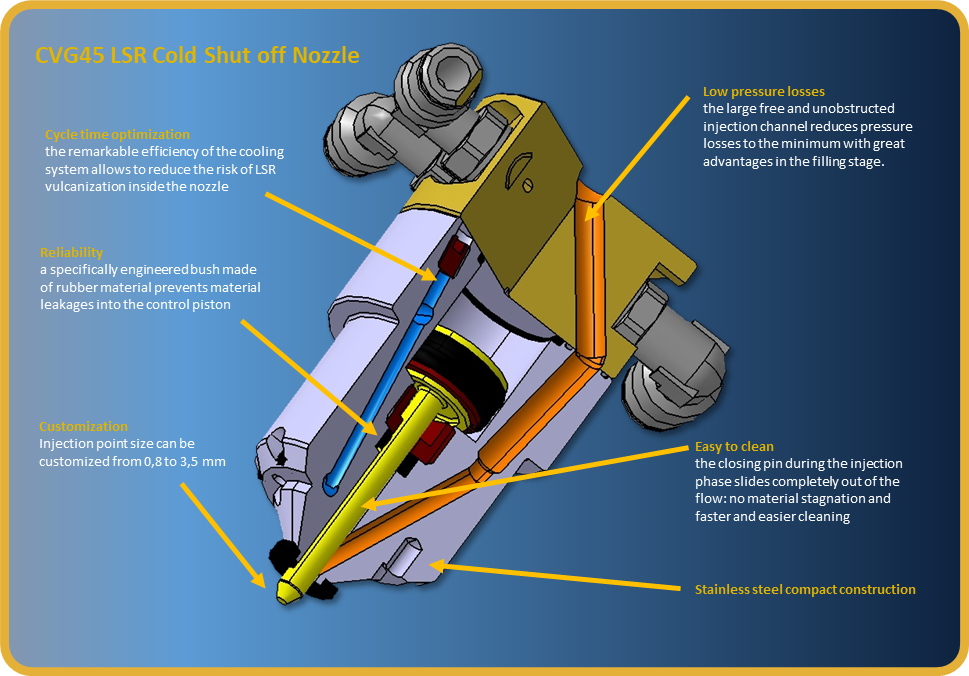

- Cold valve gate installed directly on the EasyBalance 2.0 line

- EasyBalance 2.0 control box.

- Machine or partly completed machine equipped with a Euromap 67 interface